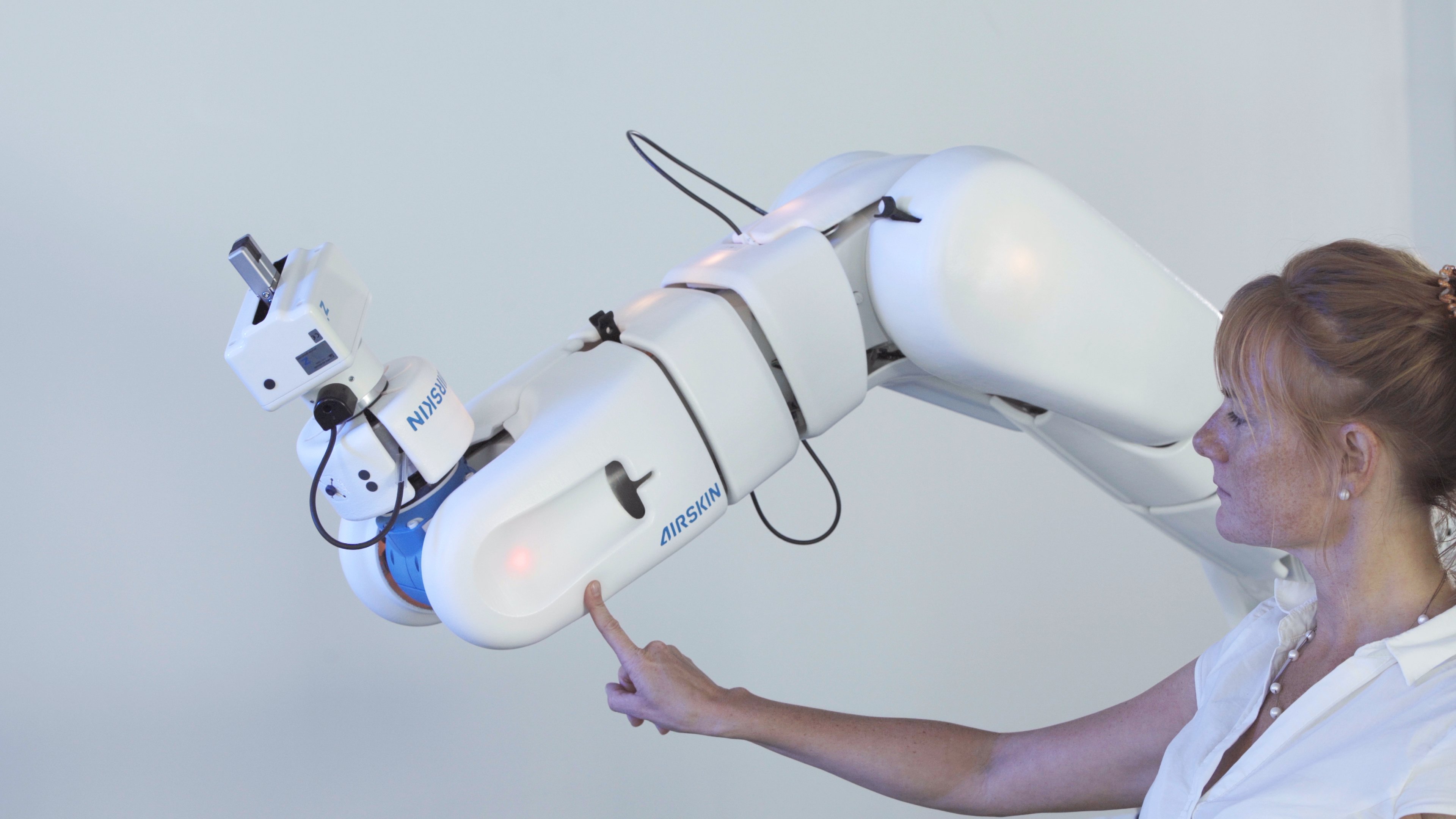

Imagine if you could easily upgrade your industrial robot to perform tasks safely together with humans, without the need for a fence. Walter Wohlkinger (PhD) and Andreas Baldinger (MSc, CEO) are making it a reality with AIRSKIN®, an innovative add-on solution that quickly transforms industrial robots into safe, collaborative robots.

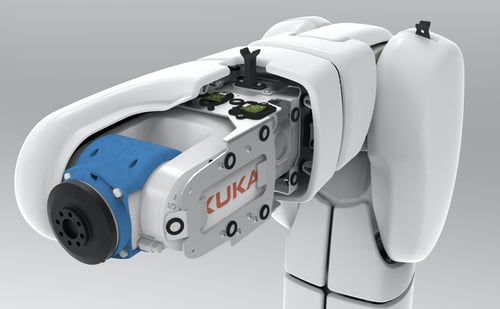

Walter and Andreas first met at university in 2011. Their mutual love for robotics was what ultimately led them to found Blue Danube Robotics in 2013. Starting out with small mobile robots to help elderly people pick up objects, they soon shifted their focus to developing safety solutions for industrial robots. In September 2015 they changed the structure of the company. They developed AIRSKIN®: a soft, pressure-sensitive skin that covers a flexible, dampening structure with smart safety electronics. The skin uses air as a sensor to detect collisions, enabling a safe workspace where humans and industrial robots can collaborate freely.

After years of building, the market has proven it’s ready for the protection, usability, and learning that the AIRSKIN provides. Today, the AIRSKIN sensor is the only one on the market that’s certified for safety.

The technology was always the number one priority for Walter and Andreas, but over the years they’ve learned it’s more about having the right team, management, and structures in place. People are part of AIRSKIN® and it’s all about making AIRSKIN® as efficient as possible to achieve the best results for our customers.

AIRSKIN has an Austrian charm, but their customers are found everywhere in Europe and beyond. Others do similar things, but are still running years behind.

‘’We are really far ahead of the competition. We believe nobody else can do this, not with the safety sensor and certification included. It’s protected, the skin and foam are soft, it’s a great service and everything is interconnected. It’s truly a great product.”

If you’ve never believed that entrepreneurship can be contagious, you haven’t met the guys behind AIRSKIN. They’re confident in what they do, and even welcome competition.

“We’re happy that there are others out there who are trying. It gives us a positive signal. It means that there’s a clear demand and need for innovation and growth.’’

At first, the corona pandemic threatened the rapid growth and 5-year mission of the company. However, Walter and Andreas, are observing many positive trends, too. Due to the pandemic demand for robots has been increasing, which furthermore will trigger space and safety concerns. As a result, AIRSKIN® will provide the perfect solution.

“We want to transform 600 to 800 industrial robots per year into collaborative robots, before 2025. Furthermore, we want to expand to different industries and move into the service industry and food preparation. We can see a clear use case for AIRSKIN with many advantages down the line there... It should be on every robot by then!’’

Visit our technology page or schedule a meeting directly on our agenda to discuss your requirements.