AIRSKIN Modules

Unlimited possibilities for fenceless automation

Flexible safety solution

Add soft, pressure sensitive, PLe / Cat. 3 safety certified AIRSKIN pads to your automation solution.

Modular add-on solution

Choose shape and thickness to fit your application. Easy-On magnetic safety.

Fast certified applications

AIRSKIN pads dampen collision, cover sharp edges, reducing force and pressure, all according to ISO/TS 15066. With a maximum of 9 ms reaction time safety is always guaranteed.

Pressure-sensitive safety elements

Experience the highest level of safety with our innovative sensor technology. AIRSKIN Modules feature advanced, soft, airtight, sensor pads that provide continuous monitoring and precise detection of internal pressure changes, instantly responding to hull deformations during collisions.

Transform your safety protocols with AIRSKIN Modules, the ultimate customizable protection for grippers, robots, and machines. Each module functions as an independent sensor, seamlessly integrated in a chain to communicate with its counterparts. Connect up to 15 pads per chain, forming a comprehensive shield against all hazards.

Adaptable and efficient, AIRSKIN Modules offer safety solution for any application. Stay protected with AIRSKIN Pads, designed to ensure safety in your workplace.

Cost–effective modular solution

AIRSKIN Modules offer a cost-effective, modular solution to quickly and easily enhance safety across a wide range of applications. Ideal for robots, custom end effectors, 7th robot axes, mobile robots, moving machinery, and other automation equipment, AIRSKIN Modules provide versatile protection.

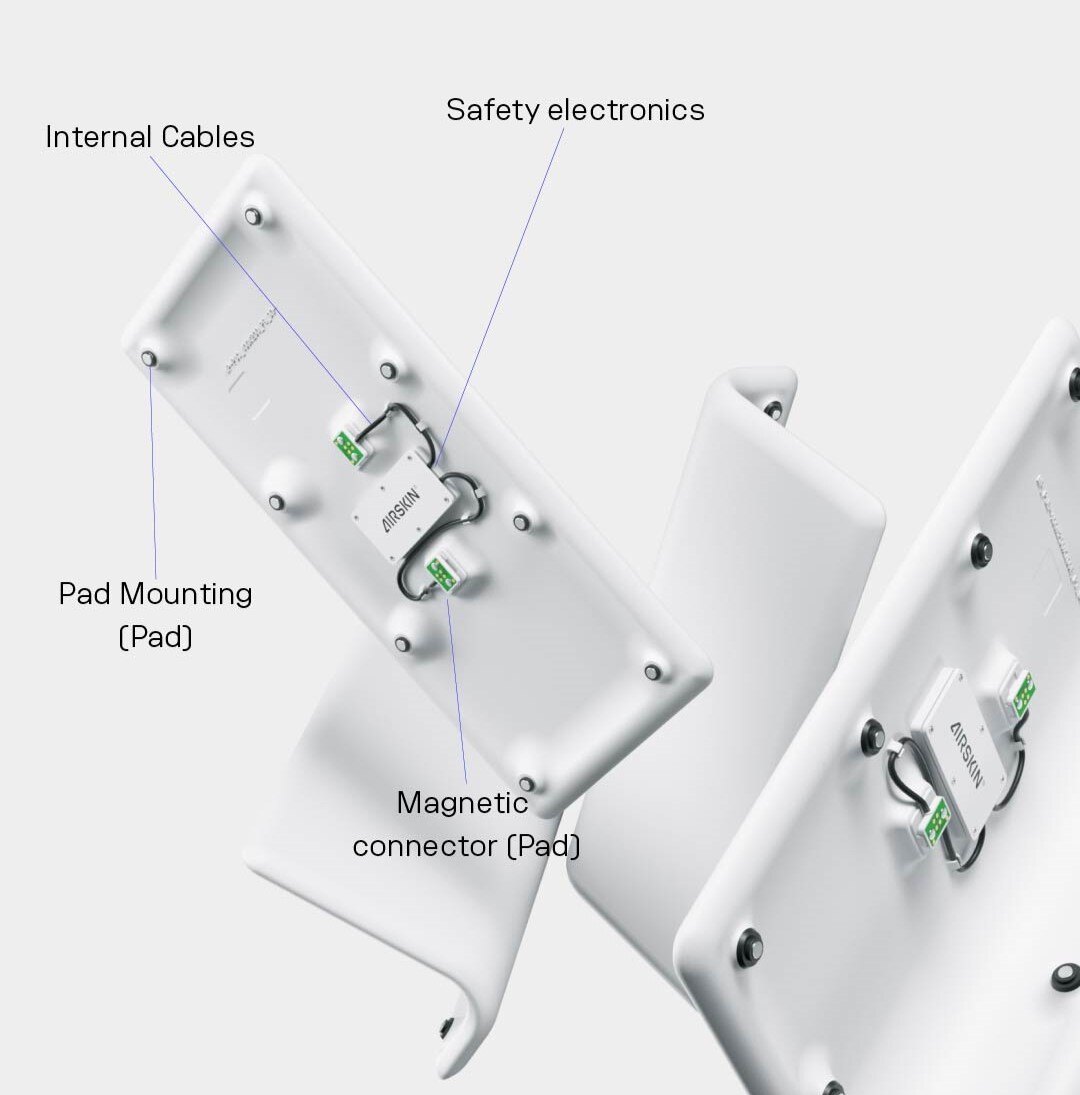

Each module comes with its own support layer, eliminating the need for additional mounting structures and reducing costs. The magnetic connectors ensure easy mounting and quick exchange of the modules. The support layers feature hole patterns compatible with any robot, machine, or gripper, so you won't need to drill additional holes.

Choose AIRSKIN Modules for a hassle-free, adaptable, and efficient safety upgrade.

Features

Magnetic

Simple to install, due to magnetic mounting and magnetic electric connectors.

Dampening

AIRSKIN pads and mounting structure are available with dampening of up to 30 mm.

Easy Installation

Direct connection of up to 15 AIRSKIN Modules as OSSD devices to any safety PLC.

AIRSKIN Modules – your flexible safety solution

The AIRSKIN Modules system is the ultimate cost-effective and flexible solution for quickly enhancing safety across almost any machinery. Each system includes connecting cables to seamlessly link the support layers, forming an efficient safety chain.

The AIRSKIN Connection Box is essential for connecting the AIRSKIN Modules system with your controller. This crucial component ensures seamless communication between the safety modules and your machinery, providing a comprehensive safety solution.

With AIRSKIN Modules, you can easily and affordably add a robust safety layer to your equipment.

Versatile AIRSKIN Modules for Optimal Coverage and Protection

We offer AIRSKIN Modules in a variety of sizes and shapes to meet your specific needs. This flexibility allows you to customize your safety solution for optimal coverage and protection, ensuring the perfect fit for any machinery, robot, or automation equipment.

Flat Modules:

- 200x100-H0

- 200x200-H0

- 300x200-H0

- 400x200-H0

Edge Modules:

- 200x160x100E-H0

- 200x200x100E-H0

- 200x260x100E-H0

- 400x200x100E-H0

- 90x300x90E-H0

- 90x400x90E-H0

Advantages

Care free solution

The AIRSKIN team can consult you, help you building your application or offer you the full care-free package for your fenceless application, even with a signed CE-marking.

Safety by the experts

With decades of experience in fenceless industrial automation and a CMSE (Certified Machinery Safety Expert) in every project, we guarantee the leading edge of safety Know-How.

Strong network

AIRSKIN is not only part of leading networks (VDMA, A3), but also cooperates with international certification bodies (TÜV, UL, CSA) and with brand names in the industry (SICK, Pilz, Keyence, ...)

Use Cases

Download the AIRSKIN Modules Product Sheet

Download the AIRSKIN Fenceless Experts flyer

Discuss your automation requirements with us

Frequently asked questions

-

Yes. AIRSKIN Modules can be used to protect clamping and shearing hazards with these linear axis.

The requirement to operate such linear axis with AIRSKIN is, that a "safe speed" can be guaranteed. This is usually the case if one uses a motor from a robot manufacturer and connects it to its robot controller, e.g. connecting the a motor as 7th axis from KUKA to the KUKA KRC.

-

Up to 15 AIRSKIN Modules can be connected in a row (we call it a lane). One lane consists of an AIRSKIN connection box and up to 15 AIRSKIN pads. If one needs more, just use more lanes. These lanes are then fed into the safe inputs of the controller (these usually have several safe IOs)

-

Download the AIRSKIN Technical Specification PDF from our request technical data page.

-

The maximum safe speed for any application is the speed at which collisions do not exceed the force and pressure limits defined in the ISO/TS 15066 for both situations: collision in free space and quasi static collisions (clamping).

The maximum speed for collision in free space is mainly limited by the moving mass. The more critical collision situation is the quasi static one. Here the reaction time and braking distance of the moving parts define the maximum reachable speed in the application.