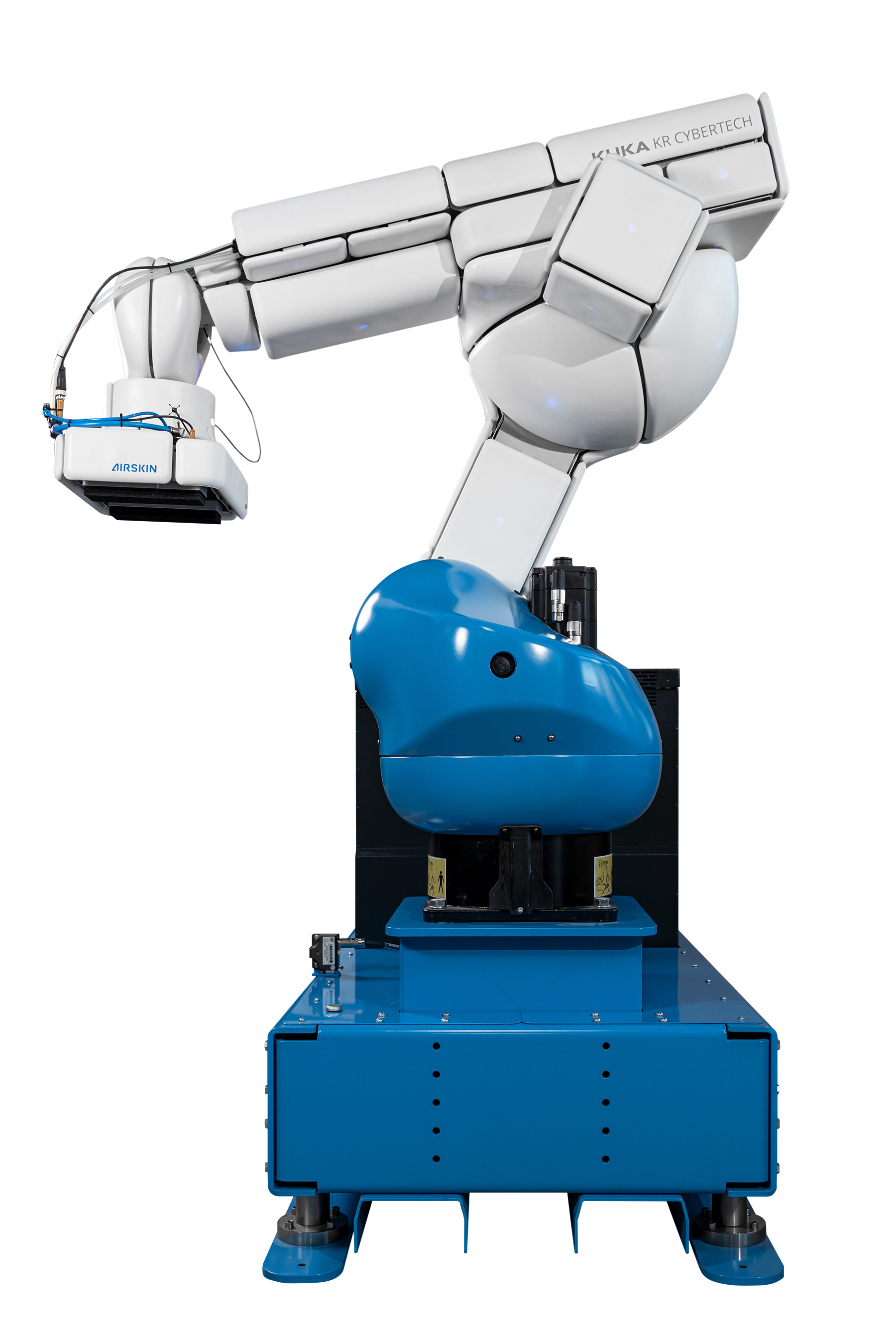

AIRSKIN Cellcore

Realizing open and flexible applications in the easiest, fastest and safest way

Unchallenged high fenceless speed

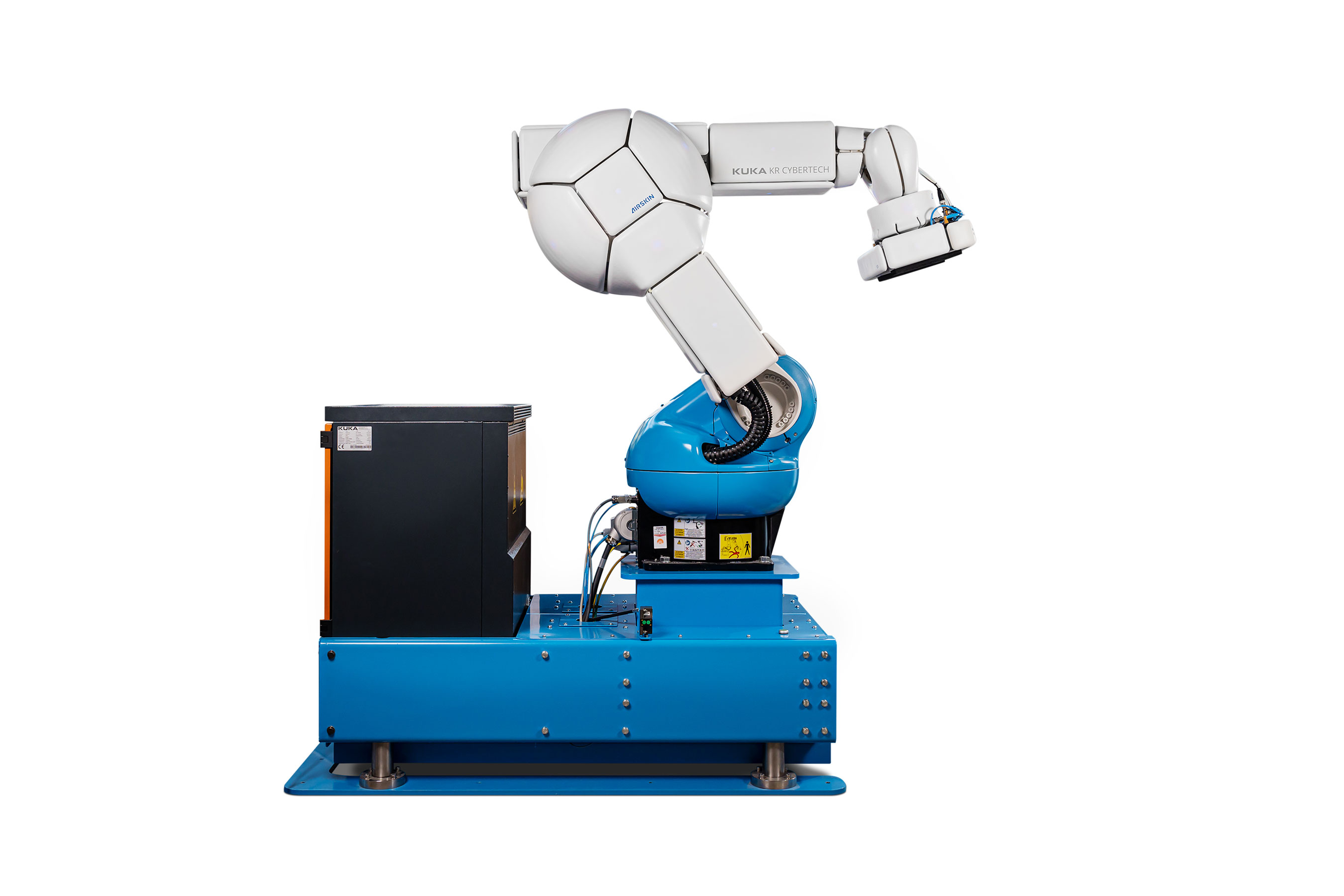

AIRSKIN Cellcore combines a KUKA Cybertech-2 robot and the new KR C5 controller on a base, and the integrated AIRSKIN allows fenceless operation.

Because the safety system is mounted directly onto the robot, it simply moves with the robot when AIRSKIN Cellcore is moved between different workplaces, and the same risk assessment applies.

Due to the unbeaten high fenceless speed of up to 2 m/s in free space, AIRSKIN Cellcore provides fenceless/collaborative robotics without compromising productivity.

AIRSKIN Cellcore can be equipped with a KUKA Cybertech model of the customer’s choice and base pedestals of different heights.

Depending on the project, AIRSKIN Cellcore can be ordered as a standalone application or can be integrated into larger projects.

Components

- KUKA Cybertech-2 robot (all models)

- KUKA KR C4/5 included

- Software packages necessary (KUKA.SafeOperation, KUKA.PalletTech)

- Cellcore Base with floor mounting plates for easy switching between workplaces

- AIRSKIN for Cybertech-2

- AIRSKIN Safetyflange (depending on application)

- AIRSKIN for tool (depending on application)

Applications & Advantages

- AIRSKIN Cellcore speeds up the planning, concept, building and integration of fenceless and collaborative robot applications significantly.

- Customers get a turnkey solution for the inner core of any fenceless and collaborative robot application: The base, the robot with controller and the already implemented safety system. And these all combined and ready to go.

- AIRSKIN Cellcore is perfect for any applications in open and flexible productions, where fences would obstruct the product flow and keep the production rigid and hard to reorganize. And, with AIRSKIN, productivity is not affected by fencelessness and collaboration.

- AIRSKIN Cellcore keeps your production humming with its unchallenged free space speed of up to 2 m/s.

Example applications are end of line palletizing, machine tending, support with production peaks between different production lines and many more.

Depending on the project, customized EoAT (End of Arm Tooling) safety systems and grippers can be developed and integrated.