Space

Compared to traditionally fenced applications, AIRSKIN can save up to 90% of floor space for other applications and humans.

Optimizing installation footprint up to 90%

With AIRSKIN, you can save up to 90% of floor space, optimizing your facility layout for maximum efficiency.

Decrease Cycletime

Upgrade your industrial robots with AIRSKIN. Collaborative movement speeds significantly faster than traditional cobots (up to 2 m/s).

Increase ROI

Save costs and increase the ROI of production cells. Add AIRSKIN to your current industrial robot, allowing advanced levels of safety with the programming interface you are already familiar with.

Ready to automate your future?

The future of production is open and flexible, which means re-arrangeable production layouts and no more fences.

AIRSKIN guarantees applications that need the lowest amount of floor space. Therefore AIRSKIN enables an open and agile shop floor that is ready for the interaction of humans, automation, robots, AGVs/AMRs and the products themselves.

AIRSKIN provides automation for numerous industry applications, which have been done manually so far - and all that without the costly moving of heavy and bulky machines to make place for fenced cells.

AIRSKIN can save up to 90% of floor space compared to fenced applications.

In terms of acquisition costs, AIRSKIN is practically the same as conventionally fenced applications, and in most cases even cheaper.

If you take into account the necessary relocation of machines to make room for the fenced application, AIRSKIN is always the more favourable solution.

And with an AIRSKIN application, production never stops, even if maintenance workers or technicians have to enter the application. Therefore, AIRSKIN also reduces the need for costly temporary production storage solutions.

Increase production density

With AIRSKIN each automated task needs extremely less floor space compared to traditional fences. Therefore, significantly more tasks can be automated in the same space: +30…40%.

Automate wherever needed

No need to move bulky production machines to make room for a fence while keeping the necessary room for safety and worker movement. With AIRSKIN, tasks can be automized right where they take place, even between already existing heavy equipment.

Open and flexible production

The production layout of the future is open and flexible for lean and agile manufacturing. Parceling up a production floor with fences contradicts the intended features. So an open space production floor is needed. By using AIRSKIN the necessary space is directly achieved.

Download the Fenceless Experts flyer

Download the technical specifications

Discuss your automation requirements with us

Frequently asked questions

-

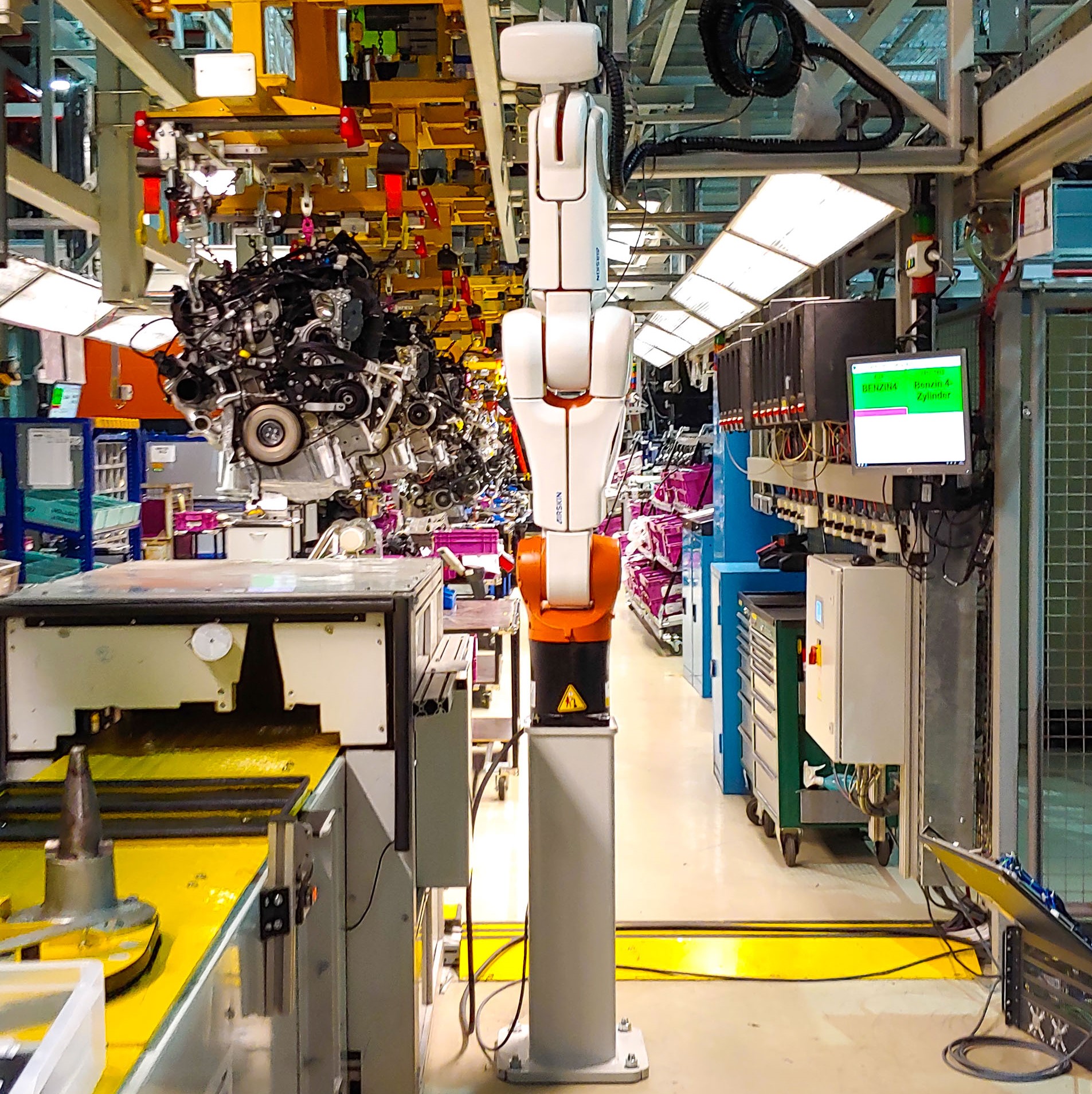

The most extreme example is quality control in automotive. The application was placed directly into the line with the footprint of the robot base, so the final space used was 0.5 x 0.5 m instead of 4 x 4 m. In most applications the reduced space is around 60-80%, where “freed-up space” is defined by floor space that can be entered by workers without interfering with the application.

-

Yes, this is never a problem with AIRSKIN. With AIRSKIN your fenceless, open and flexible applications never stop producing while taking up the least space.

-

When you want to gain space and flexibility and want to get rid of the fence in your production layout – AIRSKIN is the technology for you. When you want to achieve an open and flexible production and need more payload and higher reach than current cobots can provide, we have the solution for you.

.png?width=1200&length=1200&name=MicrosoftTeams-image%20(11).png)

.png?width=1200&length=1200&name=MicrosoftTeams-image%20(10).png)